Happy new year from ArchitectureFarm…

I’ve taken advantage of a quiet week to hunker down and get to grips with two fundamentally important Nervi projects–the Air Force hangars from 1935 and 1939-1942. These were incredibly important projects for Nervi’s technical development, but they’re confusing–a week or so with sketchup has given me a better handle on them, but there’s still plenty of figuring out to go.

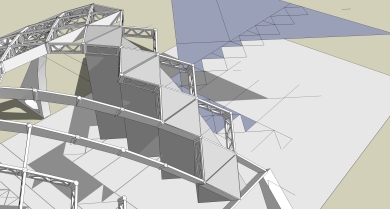

The images here never happened, of course; Nervi and Bartoli won the commission to design and build the first set of hangars (in the foreground) in 1935 in Orvieto, and the second set of hangars (background) in 1939 for Orbetello and Torre del Lago. But it seems important to see the two types next to one another, because the intervening four years saw some important changes. While the hangars are similar in form, they’re radically different in their details and their processes.

The Orvieto hangars were built entirely out of reinforced concrete, using a geodetic pattern that, as Mario Sassone and Edoardo Piccoli have shown, paralleled developments in geodetic design by U.K. aeronautical designer Barnes Wallis.[i] (Nervi served in the Italian airship corps in WWI, so this link makes sense, but so far there’s no smoking gun showing the influence…but watch this space). This structure was efficient, combining the deep, hollow shape of a concrete vault with space frame principles to create a ribbed roof shell that was relatively lightweight and hyperstatic; loads on the roof had multiply redundant paths they could follow, which made the roof impossible to calculate but super-efficient and robust even if some ribs were damaged in combat. Nervi ended up testing large-scale models of the hangars to determine their behavior, beginning an important relationship with engineer Arturo Danusso that would prove vital throughout both of their careers.

These first hangars had problems, however. They required a huge amount of formwork, since their shells had to be poured all at once to guarantee monolithic behavior. Nervi’s design for almost continuous buttressing along the hangars’ sides and backs also burned through a tremendous amount of material and timber forming, and the dead weight of the roof–even with the efficiencies of the vault and the ribs–induced bending stresses that required a substantial amount of steel reinforcing. Steel was, by 1935, a politically problematic material as Italy had few natural iron sources. The Fascist government had begun its autarchic economic policy, which stressed nationally produced materials and that was on the verge of outlawing steel even for concrete reinforcement. Finally, when the hangars entered service they suffered from thermal expansion issues. After several ceiling tiles came loose from the shells, each hangar had to have expansion joints cut into their roofs.

Each precast truss was joined to its neighbors by a poured-in-place joint that connected short rebar loops cast into each truss element. A handful of solidly cast arches provided additional stability to the system, along with a continuous edge truss that held the roof’s sectional shape. The walls of the hangar were structurally separate from the overhead roof, allowing for considerable deflection.

Each precast truss was joined to its neighbors by a poured-in-place joint that connected short rebar loops cast into each truss element. A handful of solidly cast arches provided additional stability to the system, along with a continuous edge truss that held the roof’s sectional shape. The walls of the hangar were structurally separate from the overhead roof, allowing for considerable deflection. The results were structurally efficient but also visually striking–Nervi commissioned the well-known Vasari Studio to photograph the hangars during construction, before the solid roof panels were put in place and when the roof structure, set against the sky, was almost uncannily ephemeral.

The results were structurally efficient but also visually striking–Nervi commissioned the well-known Vasari Studio to photograph the hangars during construction, before the solid roof panels were put in place and when the roof structure, set against the sky, was almost uncannily ephemeral. Despite their untimely end these hangars were, I think, the crucial moment in Nervi’s career. Between the two iterations, he made a turn from conventional, if extraordinarily competent, reinforced concrete engineering to something far more innovative. In particular, his use of precasting looked ahead to his mastery of precast ferrocemento sections that would define much of his work in the 1950s. And the astonishing vision of lightweight, even lacy concrete seemingly suspended in mid-air must have impressed upon him just how poetic this material could be.

Despite their untimely end these hangars were, I think, the crucial moment in Nervi’s career. Between the two iterations, he made a turn from conventional, if extraordinarily competent, reinforced concrete engineering to something far more innovative. In particular, his use of precasting looked ahead to his mastery of precast ferrocemento sections that would define much of his work in the 1950s. And the astonishing vision of lightweight, even lacy concrete seemingly suspended in mid-air must have impressed upon him just how poetic this material could be.

Re-building these things digitally has been a healthy bit of research on its own. Not to give too much away, but my limited sketchup abilities neatly parallel the limitations of casting and pre-casting concrete on an Italian job site in the 1930s; instead of starting off with a geodetic network, I’ve actually laid up the roofs based on Nervi’s original drawings and built a 3-d ‘scaffold’ on which I’ve placed, scaled, and rotated each family of trusses. Hunter S. Thompson once said that he’d typed out The Great Gatsby “just to get a feel for the thing,” and this is a pretty good exercise for figuring out what’s going on in buildings as well–especially when they’re made of mass produced elements and you can option-copy a single module a bunch of times.

Re-building these things digitally has been a healthy bit of research on its own. Not to give too much away, but my limited sketchup abilities neatly parallel the limitations of casting and pre-casting concrete on an Italian job site in the 1930s; instead of starting off with a geodetic network, I’ve actually laid up the roofs based on Nervi’s original drawings and built a 3-d ‘scaffold’ on which I’ve placed, scaled, and rotated each family of trusses. Hunter S. Thompson once said that he’d typed out The Great Gatsby “just to get a feel for the thing,” and this is a pretty good exercise for figuring out what’s going on in buildings as well–especially when they’re made of mass produced elements and you can option-copy a single module a bunch of times.

[i] Mario Sassone and Edoardo Piccoli, “The Grid Structures of Nervi’s First Hangars in Orvieto: Innovation in Context.” Journal of the International Association for Shell and Spatial Structures, Vol. 54, nos. 2&3. 159-168.

Pingback: Pier Luigi Nervi and the Good Hope Centre – Skinny laMinx

Hi, impressive 3D model!

There is the possibility to share it?

I would like to propose a roof in an event stage, the model would help a lot…

LikeLike

Hi, Rogerio–as a rule I don’t share 3-d models…there’s a lot invested in them. BUT, it’s not hard to recreate these in SketchUp the same way Nervi did in reality, by tracing out the skewed grid on the ground plane and transferring them up to the curve of the section…

LikeLike

Hi, no problem. I´ve asked just for gain time, modelling… but I’ll do it.

Do you know where can I find the technical drawings of the project?

Thanks!

LikeLike

Sure thing–the drawings I used were just the reprints in Nervi’s book, Aesthetics and Technology in Building. The originals–if you’re up for a trip–are in the CSAC Archives at the Università di Parma…

LikeLike

Pingback: Orbetello former seaplane base | Pigeoneyes.com

Hey, I’ve a small doubt. Could you post any links as to the feasibility of proposing such a structure in the present day? It would be helpful as I am trying to implement this kind of design for my thesis project. Thank you 🙂

LikeLike

Probably not economical today. As Sergio Poretti notes in his book Italian Modernisms, long spans like these hangars today would be more affordably built in steel instead of precast. Definitely possible, though…

LikeLike

Hi! Do you by any chance still have the 3d model of Nervi’s hangars?…aaand would you be open to share those (i guess) Sketchup files with me?

I’m from Argentina, currently studying architecture at FAPyD | UNR and it would be of great help for me and my classmate to have a 3d model of that structure: we have break it down to its core elements and show (roughly) how each of them work.

I hope you read this soon (deadline is on October 10th 😐 )

Thanks.

LikeLike

Glad to hear you’re studying the hangars! I do not share the digital models publicly, for copyright reasons, but I would encourage you to try building them in SketchUp using the long and short section drawings that you can easily find online. It is a remarkably easy structure to build since it uses repetitive components and has a simple cylindrical geometry. It should be quite easy to build by your deadline!

LikeLike

bonjour, je suis étudiante en architecture et on me demande de faire la maquette du projet de Pier Luigi Nervi à Orvieto

auriez-vous des dimensions et des infos à me faire partager ? merci d’avance

Elsa

LikeLike

Hi, sandevoir…I can’t share the models because they are based on archival plans for which I only have limited rights. The best sources of high-quality images of those plans are Nervi’s own books–especially Ernesto Rogers’ edited The Works of Pier Luigi Nervi.

LikeLike

Hello,

Could you tell me if possible the approximate dimensions of this structure ( LXB ) or the area it covers, also the dimensions of the truss and the material that was used for roofing. or if not guide me towards articles of the same.

Thank you,

Rhea

LikeLike

Hi, Rhea. The Oriveto hangars were 111.50m by 44.80m, and had integral poured-in-place concrete shell roofs. The Orbetello hangars were 102.50m x 36.90m and were covered with asphalt-concrete sheets. The plans are reproduced in several Nervi books, including Aesthetics and Technology in Building. Hope that’s helpful!

LikeLike

Yes Yes thank you so much.

LikeLike

Dear Mr. TWLeslie,

I am studying architecture at Sapienza University of Rome and I am carrying out a research about the genesis of form of Nervi’s Hangars.

Could you please give me some suggestions about the interpretation of the cilindrical form?

Thanks in advance for your help.

Best Regards,

CP

LikeLike

Hi, CP. Glad to hear you are working on the hangars–they are a rich source of information and questions. The form of the hangars was a compromise between the ideal structural form (a catenary arch) and a more economical, lower shape that used less material. It is also true that the circular cross section was easier to lay out and used less scaffolding. Nervi constantly balanced the ‘ideal’ structural shape with something he could build efficiently–this is a key moment in his ability to find a productive compromise between the two. Please keep me posted on what you find out (and, if you are working with Alberto Bologna, please give him my best!) –Tom

LikeLike