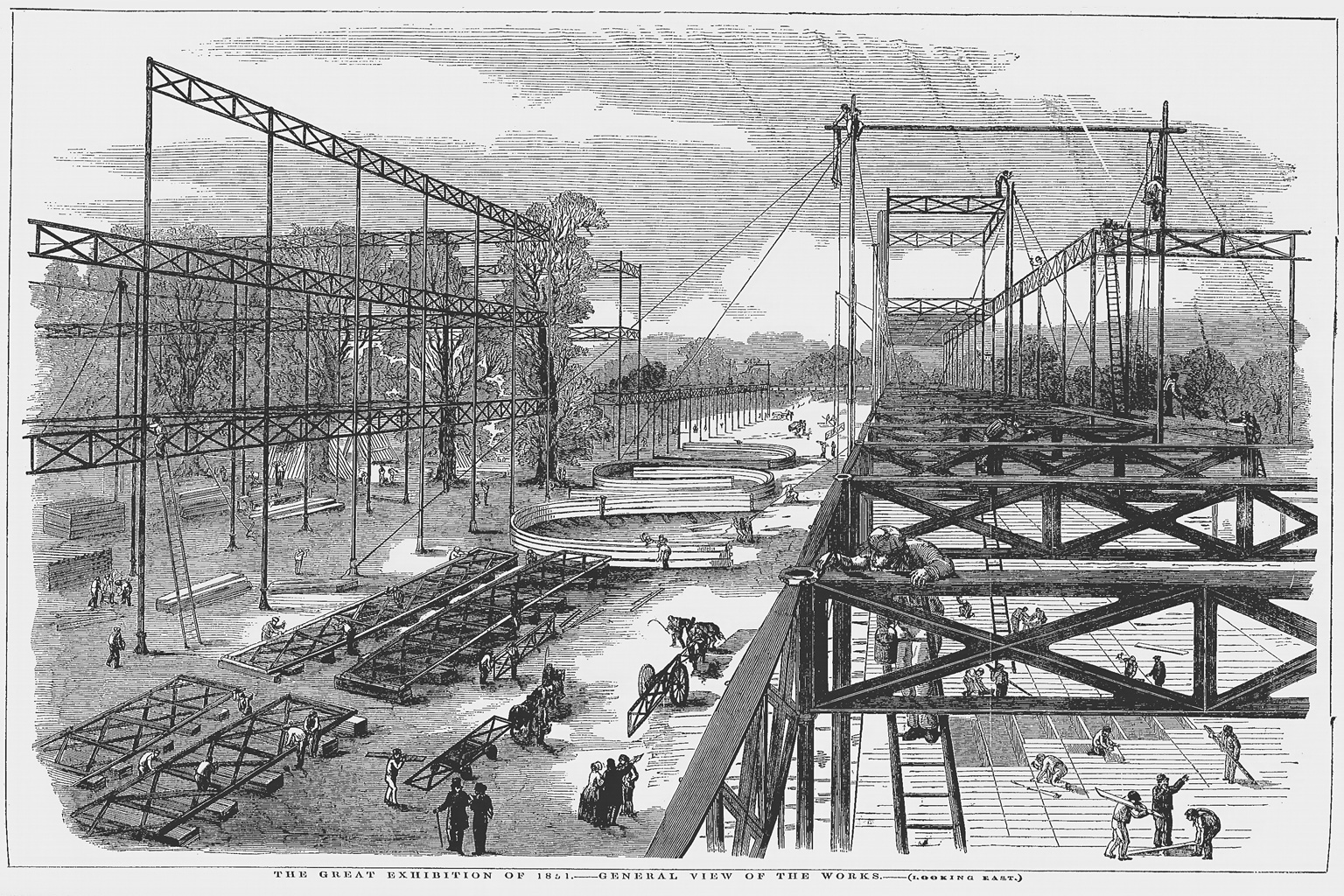

Taking a bit of a break from Chicago to read up on some early 19th century wrought and cast iron reading, and finally decided to plow through Peter Berlyn and Charles Fowler’s account of the design and construction of the Crystal Palace, an exhaustive (and exhausting) monograph put out just after the structure’s opening in 1851. I’d been curious about the trusses that spanned the relentless 24 foot planning module–they were cast iron, with connections to the columns made with pegs and shims (!). The longer spanning girders over the main nave, however, were wrought iron, which checks out–the 1840s saw that material come on line as a viable solution to spanning structures. (You can tell the difference in the engraving above if you look closely–the trussed girders to the left are clearly cast iron, bulky in proportion, while the high girder on the right, where the transept vault sits, is made up of thinner elements that could only be rolled, not cast).

Anyway, the Crystal Palace is sort of a running joke in Construction History as the “first everything,” at least if you’re British. First curtain wall? Crystal Palace. First fully industrialized building? Crystal Palace. First skyscraper? Crystal Palace. But it certainly earned its accolades–there are legitimate arguments to be made for all of those, even that last one. One way that I’d never thought of the structure being modern, though, is described brilliantly by Berlyn and Fowler early on in their design history. Joseph Paxton, after touting his idea for a mass-produced filigree of iron and glass in the London Illustrated News, joined forces with contractors Fox and Henderson just days before tenders were due for the project. While his basic scheme was as simple as it could be–just a handful of components repeated hundreds or, in some cases, thousands of times across the sixteen acre site–having confidence in the abilities of iron, glass, and timber manufactures to produce that much material in northern factories, deliver it to London in time to construct the building in just a few months, and to price it reliably, relied on technology of a far different sort:

“It was now Saturday, and only a few days more were allowed for receiving tenders. Yet before an approximate estimate of expense could be formed, the great glass-manufacturers and iron-masters of the north had to be consulted….But in a country of electric telegraphs, and of indomitable energy, time and difficulties are annihilated; and it is not the least of the marvels wrought in connexion with the great edifice that, by aid of railway-parcels and the electric telegraph, not only did all the gentlemen summoned out of Warwickshire and Staffordshire appear on Monday morning at Messrs. Fox and Henderson’s office in Spring Gardens, London, to contribute their several estimates to the tender for the whole, but within a week the contractors had prepared every working drawing, and had calculated the cost of every pound of iron, every inch of wood, and of every pane of glass.”

A first instance of Building Information Modeling? I’ll let a U.K. partisan make that argument, but it’s clear from that description that, without the telegraph and railways annihilating “time and difficulties” Paxton’s scheme could never have come together in the time it did. The railway required and inspired development in the iron industry, but easing the flow of information between manufacturer, designer, and contractor isn’t one I’d thought of before…